The Hidden Symphony of Robotic Hardware

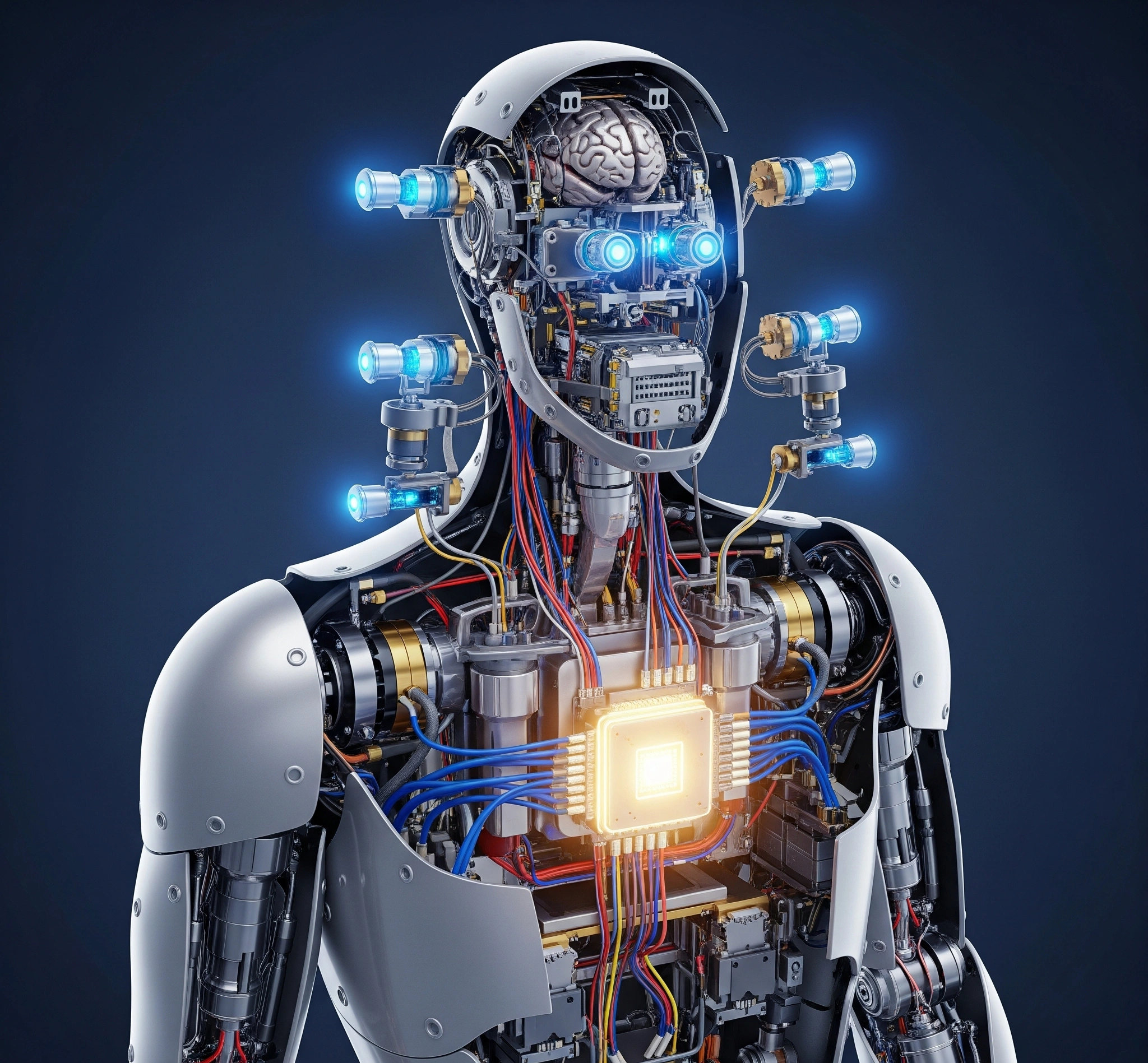

From the precise movements of industrial arms on an assembly line to the autonomous navigation of delivery robots in our cities, robots are increasingly becoming an integral part of our world. We often marvel at their capabilities—their strength, precision, and growing intelligence—but rarely do we look beneath the surface. What truly makes a robot “work”? It’s not just the sophisticated AI algorithms, but a hidden symphony of interconnected hardware components that give robots their senses, their ability to move, and their processing power. This intricate dance of circuits, motors, and sensors is the unsung hero behind every robotic feat.

For many, the internal workings of a robot remain a mystery, perceived as complex black boxes. However, understanding the fundamental building blocks of robotic hardware is crucial for anyone looking to design, build, or even just appreciate the true genius behind these machines. As a digital architect with years of hands-on experience in AI and robotics, I’ve spent countless hours dissecting, assembling, and troubleshooting these very components. This article aims to demystify the “why” and “how” behind the essential hardware that brings a robot to life. We will delve deep into the core components—from the sensors that act as their eyes and ears to the actuators that provide their muscle, and the microcontrollers that serve as their brains—offering a unique perspective and strategic insights that you won’t find elsewhere. Let’s peel back the metallic skin and unveil the fascinating internal world of a robot.

Dissecting the Core Architecture of Robotic Hardware

Every robot, regardless of its size or function, is fundamentally a system designed to perceive, process, and act upon its environment. This capability is enabled by a tightly integrated architecture of hardware components, each playing a vital role. Understanding these core pillars is the first step to truly comprehending how robots function.

1. Sensors: The Robot’s Perception Organs

Sensors are the robot’s eyes, ears, and touch. They collect data from the environment, converting physical phenomena into electrical signals that the robot’s brain can process. Without accurate sensor data, a robot is blind and deaf to its surroundings.

- Vision Sensors (Cameras):

- RGB Cameras: Capture color images, essential for object recognition, visual odometry, and general scene understanding.

- Stereo Cameras: Mimic human binocular vision, capturing two images from slightly different perspectives to calculate depth information.

- RGB-D Cameras (e.g., Intel RealSense, Microsoft Kinect): Provide both color images and per-pixel depth information, often using structured light or time-of-flight principles. Crucial for 3D mapping and obstacle avoidance.

- Distance Sensors:

- Lidar (Light Detection and Ranging): Emits laser pulses and measures their return time to create precise 2D or 3D point clouds of the environment. Ideal for mapping and long-range obstacle detection.

- Ultrasonic Sensors: Emit sound waves and measure the time for the echo to return. Cost-effective for short-range obstacle detection and proximity sensing.

- Infrared (IR) Sensors: Detect objects based on emitted or reflected infrared light. Used for proximity sensing and line following.

- Proprioceptive Sensors (Internal State):

- IMUs (Inertial Measurement Units): Contain accelerometers (measure linear acceleration) and gyroscopes (measure angular velocity). Provide crucial data for estimating the robot’s orientation, velocity, and position (dead reckoning).

- Encoders: Measure the angular position or rotation of motors and joints, providing feedback on the robot’s own movement and joint angles. Essential for precise motion control.

- Tactile Sensors (Force/Touch): Detect physical contact or pressure, allowing robots to “feel” objects or surfaces. Important for grasping, manipulation, and safety.

2. Actuators: The Robot’s Muscles

Actuators are the components that enable a robot to move and interact with its environment. They convert electrical energy into mechanical motion, providing the force and movement required for tasks.

- Motors (DC, Stepper, Servo):

- DC Motors: Simple, continuous rotation. Used with gearboxes for higher torque.

- Stepper Motors: Move in discrete steps, offering precise position control without feedback (open-loop control), but can lose steps under load.

- Servo Motors: Combine a DC motor, gearbox, and feedback control (potentiometer) to provide precise angular positioning. Widely used for robotic arms and steering.

- Hydraulic & Pneumatic Actuators: Use pressurized fluids (oil or air) to generate powerful linear or rotary motion. Common in heavy-duty industrial robots where high force is required.

- Linear Actuators: Convert rotary motion into linear motion, used for pushing, pulling, lifting, and lowering.

3. Microcontrollers & Processors: The Robot’s Brain

These are the computational units that process sensor data, execute algorithms, make decisions, and send commands to actuators. They range from simple microcontrollers to powerful embedded computers.

- Microcontrollers (e.g., Arduino, ESP32): Small, low-power, and cost-effective. Ideal for controlling individual components, managing low-level tasks, and simple robots. They have limited processing power and memory.

- Single-Board Computers (SBCs) (e.g., Raspberry Pi, NVIDIA Jetson): More powerful than microcontrollers, running full operating systems (like Linux). Suitable for complex computations, running AI models, and managing multiple sensors. NVIDIA Jetson series are particularly popular for AI-powered robotics due to their integrated GPUs.

- FPGAs (Field-Programmable Gate Arrays) & ASICs (Application-Specific Integrated Circuits): Custom hardware designed for extremely high-performance, low-latency processing of specific tasks (e.g., real-time sensor fusion, neural network inference). Used in advanced, high-end robots.

4. Power Systems: The Robot’s Lifeblood

Robots require a reliable power source to operate. This typically involves batteries and power management circuits.

- Batteries (LiPo, Li-ion): Provide portable power. Lithium Polymer (LiPo) and Lithium-ion (Li-ion) are common due to their high energy density.

- Power Management Units (PMUs): Regulate voltage, distribute power efficiently to different components, and monitor battery levels.

Understanding the Ecosystem and Implementation Challenges of Robotic Hardware

The successful integration and operation of robotic hardware components are deeply influenced by a broader ecosystem of software tools, development environments, and the inherent challenges of working with physical systems. This environment dictates the feasibility, cost, and reliability of robotic solutions.

The Software-Hardware Interface: Bridging the Gap

Hardware components are inert without software to control them. This is where the software-hardware interface becomes critical:

- Drivers and APIs: Each sensor and actuator requires specific software drivers to communicate with the microcontroller or processor. These drivers often expose Application Programming Interfaces (APIs) that allow developers to easily access sensor data or send control commands.

- Robotics Operating System (ROS): As discussed in previous articles, ROS is a widely used meta-operating system that provides a standardized framework for robotic software development. It simplifies inter-component communication, hardware abstraction, and offers a rich set of tools for visualization, debugging, and simulation.

- Firmware: Low-level software embedded directly onto microcontrollers to control basic hardware functions (e.g., motor control loops, sensor data acquisition).

Development and Prototyping Environments: From Idea to Reality

Bringing robotic hardware to life involves specialized development tools:

- Integrated Development Environments (IDEs): Tools like Arduino IDE, PlatformIO, or VS Code with extensions are used for writing, compiling, and uploading firmware to microcontrollers.

- CAD Software (Computer-Aided Design): Essential for designing the mechanical structure of the robot, housing for components, and ensuring proper fit and thermal management.

- Simulation Software: Before building physical prototypes, simulators (e.g., Gazebo, Webots, CoppeliaSim) allow engineers to test hardware designs, sensor placements, and control algorithms in a virtual environment, saving time and cost.

Challenges in Hardware Implementation:

- Integration Complexity: Combining diverse sensors, actuators, and processing units from different manufacturers can be incredibly complex. Ensuring compatibility, proper wiring, and synchronized data flow is a significant engineering challenge.

- Noise and Interference: Electrical noise from motors, power fluctuations, and electromagnetic interference can corrupt sensor readings or disrupt communication, leading to unreliable robot behavior. Careful circuit design and shielding are crucial.

- Calibration and Tuning: Every sensor and actuator has unique characteristics. Precise calibration (e.g., camera intrinsics, motor PID gains) and meticulous tuning are required to achieve accurate and responsive performance. This is often a time-consuming iterative process.

- Cost and Sourcing: High-performance robotic hardware can be expensive. Sourcing reliable components, especially for specialized sensors or custom actuators, can also be challenging.

- Durability and Reliability: Robots operate in diverse, often harsh, environments. Hardware must be robust enough to withstand vibrations, dust, temperature changes, and physical impacts. Failures in a single component can lead to system-wide breakdowns.

- Power Management: Efficient power distribution and thermal management are critical, especially for mobile robots. Overheating components or rapid battery drain can severely limit operational time and reliability.

The ecosystem surrounding robotic hardware is a testament to the interdisciplinary nature of robotics. It demands expertise in electronics, mechanical engineering, and software development, all working in concert to overcome the inherent challenges of bringing intelligent machines into the physical world. For more insights into the broader field of AI robotics, visit AI Robotics.

Diagnosing a Robotic Arm’s Precision Failure

Let me recount a challenging project experience: diagnosing and rectifying a persistent precision failure in a robotic arm used for delicate electronic component assembly. The arm, equipped with a vision system and a gripper, was supposed to place tiny surface-mount devices (SMDs) onto a circuit board with sub-millimeter accuracy. However, after a few hours of operation, its placement accuracy would degrade significantly, leading to costly errors and production line halts. This project became a deep dive into the intricacies of robotic hardware.

The Elusive Sensor Drift:

Our initial hypothesis pointed towards software bugs in the path planning or control algorithms. We meticulously reviewed the code, but found no obvious flaws. The problem was inconsistent; sometimes the arm worked perfectly, other times it drifted. We then suspected the vision system. We recalibrated the camera, but the problem persisted. It was an elusive issue, difficult to pinpoint.

The “open code” moment came when we decided to log raw sensor data from *all* components—not just the camera. We collected data from the arm’s joint encoders, the IMU, and even temperature sensors within the arm’s housing. After analyzing hours of operational data, we found a subtle correlation: the precision drift consistently began after the arm had been operating for a while, and it coincided with a slight, but measurable, temperature increase in one of the arm’s servo motors. The encoder readings from that particular joint, while seemingly within tolerance, showed a minute, cumulative error that increased with temperature.

It turned out the issue wasn’t a software bug or a faulty camera. Instead, it was a subtle thermal expansion in the gearbox of one of the servo motors. This expansion, caused by prolonged operation, led to a minute increase in backlash (play) within the gears. This, in turn, introduced a small, cumulative error in the encoder readings. The microcontroller, receiving slightly inaccurate position feedback from the encoder, would then command the actuator to move to a slightly incorrect position, leading to the precision drift. Our initial debugging focused too heavily on software and external sensors, overlooking the subtle physical changes within the core robotic hardware.

The Actuator-Microcontroller Feedback Loop Conundrum:

Once we identified the thermal expansion as the root cause, the solution wasn’t as simple as replacing the motor. The client needed a more robust, long-term fix. We realized we needed to compensate for this thermal drift in real-time. This involved a deeper dive into the actuator-microcontroller feedback loop.

We implemented a dynamic compensation algorithm directly on the arm’s microcontroller. This algorithm used the temperature readings from the affected motor to predict the expected backlash increase. It then applied a tiny, real-time correction factor to the position commands sent to the servo. This required careful tuning of the compensation model and extensive testing under various thermal loads. The microcontroller, previously just executing PID control, now also performed a real-time, temperature-compensated adjustment to its output. This iterative process of diagnosing a subtle hardware flaw, understanding its impact on the control loop, and implementing a software-based compensation at the microcontroller level was crucial to restoring the robotic arm’s consistent sub-millimeter precision. It underscored that true robotic intelligence lies not just in high-level AI, but in the meticulous engineering of its underlying hardware and the precise control loops that govern its physical interactions.

The Unseen Vulnerabilities of Robotic Hardware

The seamless operation of a robot often belies the profound, often unseen, vulnerabilities inherent in its physical components. The “open code” moment reveals that while algorithms provide the intelligence, the hardware is the fragile vessel carrying that intelligence into the unpredictable real world. These are the “why” behind the continuous pursuit of more robust materials, more precise manufacturing, and more intelligent hardware-software co-design that often go unstated in popular discourse.

1. The Reality: The Enemy Within:

Unlike software, which doesn’t degrade with use, robotic hardware is subject to constant physical stress. Motors wear out, gears develop backlash, bearings seize, and wires fray. The paradox is that the very act of a robot performing its function inevitably leads to its own degradation. The unseen battle is designing components for extreme durability, implementing predictive maintenance algorithms (using sensor data to forecast failures), and developing self-healing or reconfigurable hardware that can adapt to wear and tear. This pushes the boundaries of materials science and embedded diagnostics.

2. The Environmental Gauntlet: The Unpredictable Outside:

Robots often operate in environments far harsher than a clean lab. Dust, humidity, extreme temperatures, vibrations, and even electromagnetic interference can wreak havoc on sensitive electronics and mechanical parts. The paradox is that while we design robots for specific tasks, the real world is a chaotic gauntlet of unforeseen environmental challenges. The unseen battle is ruggedizing hardware, implementing robust sealing and thermal management, and designing sensors that can maintain accuracy despite external disturbances. This requires meticulous environmental testing and robust error handling at the hardware interface.

3. The Precision vs. Cost Trade-off: The Economic Reality:

Achieving high precision in robotic movements and sensor readings often comes at a significant cost. High-resolution encoders, low-backlash gearboxes, and industrial-grade sensors are expensive. The paradox is that while technological advancements enable incredible precision, economic realities often force compromises. The unseen battle is innovating in design and manufacturing to achieve “good enough” precision at an acceptable cost, or developing intelligent software compensation techniques that can mitigate hardware imperfections without relying solely on expensive components. This involves clever calibration routines and adaptive control algorithms.

4. The Interdisciplinary Chasm: Bridging the Silos:

Robotic hardware development requires a deep understanding of mechanical engineering, electrical engineering, materials science, and computer science. The paradox is that these disciplines often operate in silos, leading to suboptimal designs or integration headaches. The unseen battle is fostering truly interdisciplinary teams and methodologies where hardware and software engineers collaborate from the earliest design stages. This ensures that the robot’s physical form factor, sensor placement, and actuator choices are optimized for the software algorithms they will run, and vice versa. This holistic approach is critical for building truly robust and efficient robots.

The “open code” of robotic hardware reveals that building truly functional and reliable robots is not just about writing intelligent software; it’s about grappling with the inherent vulnerabilities of physical systems, continuously innovating in materials and design, and fostering deep interdisciplinary collaboration to overcome the unpredictable challenges of the real world. This ongoing struggle defines the cutting edge of robotics engineering.

An Adaptive Framework for Robust Robotic Hardware Design

Designing and implementing robust robotic hardware requires a strategic, adaptive framework that anticipates challenges and integrates solutions across the entire system lifecycle. Here’s a practical framework for engineers and innovators aiming to build reliable and high-performing robots:

1. Embrace Holistic Co-Design: Hardware and Software in Harmony:

- Early Interdisciplinary Collaboration: Foster tight collaboration between mechanical, electrical, and software engineers from the initial concept phase. Hardware choices should inform software architecture, and software requirements should drive hardware specifications.

- Simultaneous Prototyping (Digital & Physical): Utilize advanced CAD/CAE tools for digital prototyping and simulation of mechanical and electrical systems. Concurrently, build rapid physical prototypes using 3D printing and off-the-shelf components to validate core concepts and identify physical constraints early.

- Design for Manufacturability & Assembly (DFM/DFA): Consider manufacturing processes and assembly ease during the design phase. This reduces production costs, improves quality, and simplifies maintenance.

2. Prioritize Sensor Redundancy, Fusion, and Calibration:

- Multi-Modal Sensor Suites: Integrate diverse sensor types (e.g., Lidar, cameras, radar, IMU, force sensors) to provide complementary data and redundancy. This improves robustness against individual sensor failures or environmental limitations.

- Advanced Sensor Fusion Algorithms: Implement sophisticated probabilistic filtering techniques (e.g., Kalman Filters, Particle Filters, Graph-based Optimization) to fuse noisy and incomplete sensor data into a robust, real-time understanding of the robot’s state and environment.

- Automated Calibration Routines: Develop and integrate automated or semi-automated calibration procedures for all sensors and actuators. This ensures consistent accuracy over time and simplifies field deployment.

3. Design for Durability, Maintainability, and Environmental Resilience:

- Ruggedized Components & Enclosures: Select industrial-grade components and design enclosures that protect sensitive electronics from dust, water, vibrations, and extreme temperatures, matching the robot’s operational environment.

- Modular Design for Serviceability: Design the robot with modular components that are easy to access, replace, or upgrade. This simplifies maintenance, reduces downtime, and extends the robot’s lifespan.

- Thermal Management: Implement effective cooling solutions (e.g., heat sinks, fans, liquid cooling) to prevent overheating of processors, motors, and power electronics, which can degrade performance and reliability.

- Predictive Maintenance Integration: Embed sensors (e.g., temperature, vibration, current) to monitor the health of critical components. Use this data with AI/ML models to predict potential failures, enabling proactive maintenance and minimizing unexpected downtime.

4. Optimize Power Systems and Edge Computing:

- Energy-Efficient Actuators & Control: Choose energy-efficient motors and design control algorithms that minimize power consumption while maintaining performance.

- Smart Battery Management: Implement intelligent battery management systems that optimize charging cycles, monitor battery health, and provide accurate remaining charge estimates for mission planning.

- Distributed Computing & Edge AI: Distribute computational tasks across multiple processors (e.g., dedicated microcontrollers for motor control, SBCs for high-level AI). Leverage specialized AI accelerators (GPUs, NPUs) for efficient, low-latency inference at the edge.

By adopting this adaptive framework, engineers can strategically address the multifaceted challenges of robotic hardware design, moving beyond individual components to build truly robust, reliable, and high-performing robots that seamlessly integrate with their intelligent software. For more insights into the broader field of AI robotics, visit AI Robotics.

The Enduring Foundation of Robotic Innovation

The journey inside a robot reveals a fascinating world where intricate hardware components form the enduring foundation of robotic innovation. We’ve dissected the vital roles of sensors as their perception organs, actuators as their muscles, and microcontrollers as their brains, all sustained by robust power systems. Crucially, we’ve unmasked the unseen vulnerabilities: the relentless wear and tear, the unpredictable environmental gauntlet, the economic trade-offs of precision, and the critical need to bridge interdisciplinary silos. These are the profound challenges that define the cutting edge of robotic hardware engineering.

As robotics continues its exponential growth, from industrial automation to personal assistance and exploration, the demand for deeper understanding and more robust hardware solutions will only intensify. The true digital architect in this domain is not merely a coder of algorithms but a visionary who understands the holistic interplay of physical design, material science, electrical engineering, and intelligent software. They continuously push the boundaries of what these machines can physically achieve. Your next breakthrough in robotics will not just be about a new AI model. It will be about the strategic foresight and adaptive frameworks that enable truly resilient, precise, and functional robotic hardware, embarking on an ever-unfolding odyssey of innovation at the intersection of bits and atoms.